Feasability study for

the implantation of a system of pneumatic waste collection in FERNBANK (OTTAWA)

September 2009

in

many cities of the world the waste have been continued processing just as for a

century

The new technologies maintain

the urban infrastructure in continuous development and contribute to improve

the environment. At the same time, it is paradoxical that we keep collecting

and transporting our waste in the same way as one hundred years. We store them

outside or inside the place in which we live, in open containers. Later, they

are collected manually for its transport in heavy and noisy trucks that pass

through residential areas and downtown of the cities.

The new technologies maintain

the urban infrastructure in continuous development and contribute to improve

the environment. At the same time, it is paradoxical that we keep collecting

and transporting our waste in the same way as one hundred years. We store them

outside or inside the place in which we live, in open containers. Later, they

are collected manually for its transport in heavy and noisy trucks that pass

through residential areas and downtown of the cities.

The load that supports our urban surroundings, grows to a very fast rate. Every time we generated more remainders and we used

more disposable packages. Often we don´t know how to avoid the piles of waste

that seem to grow in our streets and seats. The hygiene problems that this

produces are considerable.

The load that supports our urban surroundings, grows to a very fast rate. Every time we generated more remainders and we used

more disposable packages. Often we don´t know how to avoid the piles of waste

that seem to grow in our streets and seats. The hygiene problems that this

produces are considerable.

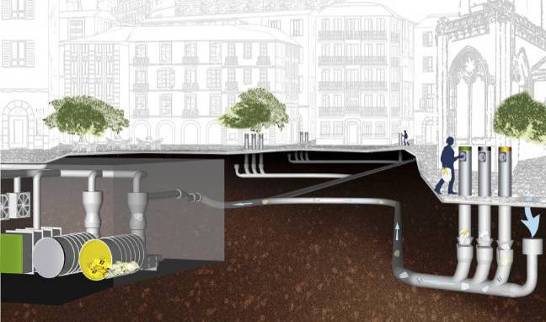

The

solution is in the subsoil

At the beginning of

the sixties, Envac introduced the innovation that revolutionized the waste

collection in big areas of the world: The first close and subterranean waste

collection system.

Underground

pneumatic systems can be installed to collect the waste with the same

naturalness with which the subterranean systems for the sewage system, the

water, electricity and telephone lines are installed.

Underground

pneumatic systems can be installed to collect the waste with the same

naturalness with which the subterranean systems for the sewage system, the

water, electricity and telephone lines are installed.

New draughts for the strategy of sustainable

surroundings

New draughts for the strategy of sustainable

surroundings

On paper, Envac

gives a system to manage the waste that will stay in operation during a minimum

of 30 or 40 years. But in practice, the system is a “much more important

product”: an improvement of the environment that not only hits on the city and

its inhabitants, but also on the global cycle.

In order to reach

this objective we must perceive to our clients like our partners; an

association model that is only possible if we shared the same idea of how we

want that the management of our waste works. A Envac installation entails a

commitment in a long term.

The

promise of sustainable surroundings

We had been more

than 40 years working in the achievement of rational solutions for our clients; solutions that are sustainable

in ecological terms, social terms and economic terms. From the beginning, in

1961, to today, we have a total of almost 600 installations in more than 30

countries. Around 30 have been working more than 35 years on continuous form

and they will follow working in that way during long time more. For us this is

irrefutable test of the trustworthiness of our ecological promise.

REMOVING WASTE – CREATING

VALUE

In the sixties Envac had

already been developed and installed the first system of underground transport

of remainders for residential zones and hospitals. These systems still working,

proving with it, the trustworthiness,

sustainability and operative security of the technology.

World-wide presence with 30

offices in 16 countries

From

its beginnings, Envac has been growing to become a company of world-wide scale,

with 30 present offices in 16 countries. The most important factor for our growth has been our experience and

knowledge in the matter of pneumatic waste collection. We have been creating a

unique base of references in the world with 600 installations for 40 years. They

are our greater assets, followed of the specialization and commitment of our

workers. In contrast to any other company of the world, we have the capacity to

demonstrate that the systems of pneumatic waste collection take to many decades

improving the management of remainders for hundreds of thousands of people.

Thanks to it, our clients can count on an unquestionable security in their

process of decision making.

AGFA

Sector of Aranjuez - Madrid. Envac has installed a system of pneumatic collection

in this town council declared Heritage Site by Unesco. The installation of AGFA

Sector in Aranjuez collect the waste of 1.700 houses and the terminal has these

solar paneles that cuold produce 50 Kwh

INDEX

Content

2. Description of Envac Systems

5. Description of the proposed solution

6.3. Specifications to fulfill in the Building

7.1. Estimated budget removing 2 fractions

7.2. Estimated budget removing 3 fractions

1.

Object

The Fernbank

Community study area is proposed to encompass approximately 650 hectares of

land between the established communities of Stittsville, Kanata West and Kanata

South, and extending south from Hazeldean Road to Fernbank Road.

The recommended Fernbank Community Design Plan

reflects an urban community containing a population of approximately 28,027 to

31,351 residents, and approximately 9,718 to 10,977 dwelling units and 2,497 to

2,623 jobs.

The recommended Fernbank Community Design Plan

reflects an urban community containing a population of approximately 28,027 to

31,351 residents, and approximately 9,718 to 10,977 dwelling units and 2,497 to

2,623 jobs.

The objetive of the

document is the carry out of a preliminary study for the running of an Envac´s

pneumatic waste collection for Fernbank.

The study is made from

the economic and technical point of view.

The

information used for the study is enough for a rough estimation, but for

further analisys would be needed Cad drawings and the number of dwellings per

plot.

The

information used for the study is enough for a rough estimation, but for

further analisys would be needed Cad drawings and the number of dwellings per

plot.

2.

Description of

Envac Systems

The Envac system is

totally watertight, eliminating therefore the bad smells and dirty that

normally is produced inside the refuse room and in the containers in the

street. The waste is introduced through floodgates located outside or inside

the buildings. When the waste is thrown in the inlets nobody will get in manual

or visual touch with it. The classification of each fraction is made in origin,

using a specific inlet for each fraction.

The Envac pneumatic waste

collection systems are based on a network of pipes through which a powerful

airflow is in charge to transfer the waste to final point, where they are

stored in containers. The inlet doors to deposit in the system the waste can be

installed in all the plants of the buildings, in locations that are considered

more interesting for the operation of them.

When the exhausters

installed in the Collect station, are put into operation, and them create in

the system an airflow that allows the transport of the waste to the Collect

Station. Each valve of temporary storage is emptied in few seconds.

The system allows the

selective collection of different fractions of waste. All types of remainders

can be transported by the system, except the glass that cannot be collected as

separated fraction because it is a very erosive material and therefore it would

reduce the life of the installation.

By means of the system of

pneumatic collection, the waste is transported, by aspiration within

underground pipes, from its place of origin to a collect station, where they

are introduced in big containers

The pneumatic waste collections are made up of three

different parts:

þ

Inlet points

þ

Pipe network

þ

Collect station

Collect station

Inlet Points

Inlet Points

The inlet points can be

located inside the buildings or like inletboxes in the public roadway,

depending on if it is a new urbanization area or consolidated area.

The waste is introduced

through the inlet doors. The vertical chutes connect these inlet doors with the

waste valves, located in the basement of the buildings.

The valves normally are

closed and they are opened during 7 to 10 seconds during the cycle of

collection, that usually is repeats two or three times to the day. When the

valves are closed, the waste that falls by gravity through the vertical chutes

is stopped by the valve element of closing until the operation of collection

starts.

When the valve is opened,

the waste fraction falls by gravity / aspiration in the airflow of the

transportation pipe. In the end of each branch of pipe an air valve is

installed, the air valve regulates the air entrance to the system, with the

intention of create the air current.

The pipe network is made up by steel pipe of

diameter 500 mm and variable thickness. The correct determination of this

thickness has a great importance, due to the considerable erosion that high

speed of the waste, that circulate through the pipe, causes. Anyway, this high

speed does that the bends and the branches of the network must have certain

geometric conditions.

In big networks, Sectioning Valves, that isolate

the main braches of the pipe network, are installed.

Collect Station

In the collect station all the equipments are installed for make the aspiration of the waste, separate it of the air and compact it inside the containers. From the collect station, the signal and the necessary compressed air to drive all the elements that make up the system are provided.

In the collect

station, the waste is separated of the air of transport in the waste separator

that is made up of a cyclon and rotative screen.

In the collect

station, the waste is separated of the air of transport in the waste separator

that is made up of a cyclon and rotative screen.

Once the waste and the air are separated, fall

into compactor and that introduces and compact them inside big containers. An

automatic transporter is in charge to replace the full containers by other

emptinesses.

The aspiration that makes the pneumatic

transport of the waste possible from the different points to collect station is

made by the serial connection of the exhausters. Later, the sucked air pass

through a synthetic filter where the particles of dust are eliminated and

before be expelled to the outside, the air pass through a silencer

A compressor with auxiliary equipments provides

compressed air that activates all the valves located throughout the network

The collection process, that works

automatically, is controlled and supervised by the control system with

computer. By means of a modem, this equipment can be connected to another

control system at a distance.

The only operation that requires labour is the truck

that transports the full containers to the disposal place. Once the containers

are empty, they are located again in the terminal.

3.

Types of

Installations

The modern pneumatic

waste collection systems with selective collection, can be installed in residential

areas that vary between 200 and 8.000 dwellings.

In big areas, from 600 to

10.000 dwellings, are used systems with pipes of transport with a diameter of

400 mm or 500 mm. In this type of installations, named “Big Systems of

Pneumatic waste Collection with Selective Collection”, the different fractions

of waste are transported by an only one network without previous treatments or

trituration.

In small areas, from 200

to 600 dwellings, are used systems where the diameter of the pipe of transport

is small, 400 mm. In this type of systems named “Small Systems of Pneumatic

waste Collection with Selective Collection", the different fractions of

waste are transported by an only one network with previous treatments or

trituration.

Three types of systems of

collect stations exist, offering three alternatives by combination of

equipments:

F System

The main characteristic

is the absence in the collect station of compactors of waste and cyclons, due

to this all the equipments are located in a single plant. It does not need any

device of movement of containers. It is conceived to offer service to a maximum

number of houses of 1,200 with selective collection of 1, 2 or 3 fractions.

G System

This collect Station is

conceived to offer service to a maximum number of equivalent dwellings of

3.500. The difference of G system regarding F system is that the separation of

the air and the waste are made in a hopper that directs the waste to the

compactors. All the installation is developed in a simple plant with an

approximated vertical clearance of 5 meters.

C System

Collect Station with

waste compactors and cyclons, these cyclons will be located in the upper floor.

The movement of containers can be made with bridge crane or with a conveyor of

containers in the case of collect stations with the two plants in surface.

This power station is

conceived to offer service to 8,000 equivalent dwellings, with possibility of

selective collection of 1, 2 or 3 fractions. If the number of dwellings is

exceeded, it will be necessary to require the equipments of two collect

stations, being able to locate in two separate collect stations or in shared

building.

4.

System Advantages

The environmental

technical justification of the implantation of the system comes with the

following benefits that the action entails.

Sustainability

The automatic waste

collection represents a very clear differential note respect to the traditional

collection of waste. It contributes perfectly to one better quality of life of

the citizens and is integrated in the SUSTAINABLE

CITY concept.

Elimination of negative effects

It eliminates the

negative effects of the traditional systems of waste collection: noises, bad

smells, problems of traffic, etc.

A profitable investment

ENVAC is an extremely

effective system. It allows to a better use of the space and a more rational

waste handling, as well to reduce substantially the operation cost.

Better environment

Waste is transported

underground in the ENVAC hermetic system; thanks to this we increase the

aesthetic aspect of the area and its hygiene. We avoid foul smelling problems

and all the other aspects related with the waste collection rooms or containers

on the streets.

Service to the user

It provides to the user a

service where the system arrives until its house or a close point of it.

Flexibility

and life of the installation

It is flexible to the

changes, lasting in time, reliable and adaptable to the selective collection of

different fractions.

Separation of the fractions

It makes easy the

separation in origin of the waste fractions, contributing to the recycled.

Available 24 hour per days

The discharge points are

located close to the user, inside the buildings or in the street, and they are

emptied automatically whenever needed. The ENVAC system is available 24 hours

per day, 365 days per year, thanks to its reliability.

More free space

We free rentable space

both public and inside buildings, which can be used for more creative and

efficient aims, as green areas or pedestrian areas.

It avoids contact with the waste

Once the user introduces

the waste in the system, nobody already returns to have manual or visual

contact with it.

Reduction of the heavy traffic

Using pipelines to

transport waste to the collection station, we reduce the heavy truck’s traffic.

Reducing air pollution and the noise level and we increase the safety and the

comfort of the area inhabitants.

Better

health and work environment

Using an ENVAC system to

collect waste sensibly increases health and quality of the job. Nobody enters

in manual or visual contact with the refusals.

Therefore, the viability

of the implantation of the system, from all the points of view, is clear,

although it is difficult and complex to carry out with detail an evaluation

cost/benefit, due to some of the benefits are hardly to quantify.

.

5.

Description of

the proposed solution

5.1.

Scope

This study tries to give

a solution to the collection of the urban waste generated in the new

development areas located in Fernbank (Ottawa).

The system of pneumatic waste collection demands the installation of two

collection stations. In this feasibility study we propose a place to locate

these terminals.

The system of pneumatic waste collection demands the installation of two

collection stations. In this feasibility study we propose a place to locate

these terminals.

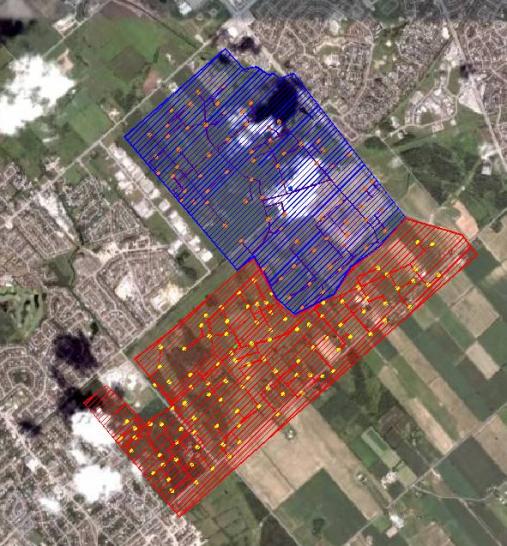

The terminal 1 will be

removing an area of 335 HA (in red color in the picture) and the terminal 2

will be removing an area of 315 HA (in blue color in the picture).

![]()

5.2.

Departure

data

Departure data used has

been the tables “Dwelling Unit Projections” and “Population Projections” of the

document “Fernbank Community Design Plan”.

6.

Design Plan.

SYSTEM DESIGN TO COLLECT FERNBANK - A NEW DEVELOPMENT AREA IN OTTAWA.

According with the info received, we have designed two systems, this

mean to build two terminals, because total area has 12.587 equivallent dwelling

(residential and commercial use and services sector)

According with the info received, we have designed two systems, this

mean to build two terminals, because total area has 12.587 equivallent dwelling

(residential and commercial use and services sector)

The systems that will give

service to collect 3 fractions (recyclables, organic and rest) of the complete

development.

We propose a economical

option to collect only 2 fractions.

The total pipe network

will have around 36.000 meters of pipe with a diameter of 500 mm.

The location of the

inlets will be in the street, with the exception of some inlet points that will

be inside the building, depending of type residential area.

One of the preliminary

conditions in the layout of the pipe network is that it must be straightest

possible trying to reduce costs of installation, energy consumption and erosion

in the pipe.

For the execution of the

pipe networks it will be necessary execute digging workings, construction of

lodging wells of the inspection openings, construction of the chambers for the

air entrance to give service to the installed inlet boxes in the street, and

the construction of chambers for the sectioning valves.

The depth of the pipe network could be variable due to the pneumatic

waste collection system allows the reverse-slope collection. The maximum slope

admitted is approximately 20%. In any case and to avoid deformations by traffic

loads the bottom of the pipe would not have to be to less than one meter of the

ground level without protection of a concrete slab. In any case, like in the

plant drawings, the profile of the network must be the flattest possible,

within the possibilities, due to this will suppose a smaller power consumption

and a smaller erosion of the materials.

The depth of the pipe network could be variable due to the pneumatic

waste collection system allows the reverse-slope collection. The maximum slope

admitted is approximately 20%. In any case and to avoid deformations by traffic

loads the bottom of the pipe would not have to be to less than one meter of the

ground level without protection of a concrete slab. In any case, like in the

plant drawings, the profile of the network must be the flattest possible,

within the possibilities, due to this will suppose a smaller power consumption

and a smaller erosion of the materials.

Nevertheless in those

points in which the inlet boxes are located on the streets the ditch level will

have to be of 2.75 meters of depth.

The chambers of the

sectioning as well as the chambers for the location of the air valves will have

to be executed to guarantee the water tightness of them.

The well of the inspection

openings will be located to a maximum distance among them of 80 meters. Next to

the inlet boxes groups an inspection opening will always be located.

According to the

requesting to which the pipes are exposed, the materials to use will be the

next ones:

The straight pipe will be

of carbon steel, helicoidally welded with a machine type HELIXWELD with double

internal and external welded seam cordon by the procedure called “sumerged

arc”. The quality must be DIN St 37.2 or according with the Swedish norms SIS

1312 o ASTM A 105 grades B.

Also is permissible,

mainly in great thickness, straight pipe with a longitudinal welded, also with

double internal and external welded.

The thickness of the wall

can range from 5 to 22 mm depending the stretch of the installation. The

internal diameter of the pipe will always be 498 mm.

Bends with a spirally or

longitudinally welded, with quality St 52.3, or according with the Swedish

norms SIS 2101, o ASTM A 155 grade CMSH 70/1:

þ

Internal diameter

.................. 498 mm

þ

Thickness of the

wall.................. De 8 a 18 mm

þ

Radius of

continue curvature ...1.800 mm

þ

Angle of

curvature ..............From 10° to 90°

þ

Treatment of the

surface .......Polyethylene 3 layers coating or similar.

The bends will be of

continue circular curvature of carbon steel, made from helicoidally welded

pipes according with the chapter of straight pipes. In any case mitred bends

will be accepted.

The bends of this

material will have a minimum thickness of 8 mm and a maximum thickness of 18

mm.

The radius of curvature, measured in axis, will not be less to 1,800 mm

for this material.

Ni-Hard metal Bends

The Nihard material of

high hardness is adapted for those points where steel ST 52,3 cannot assure a

life expectancy superior to 30 years.

The minimum radius of

curvature is 1500 mm with thicknesses from 18 mm.

The join of the Nihard

material will be realised by the special connection, but never by welded.

Prefabricated conections

of straight pipes. The lenght of the main part is 2,5 m and the lenght of the

part of the conection is 1,5 m. The angle between the main part and the

connection part is of 30º.

þ

Internal Diámeter

...................... 498 mm

þ

Thickness of wall

......................From 5 to 22 mm

þ

Treatment of the

surface ...........According straight pipes

They are prefabricated

pieces of straight pipe in agreement with their specifications, made up of a

main stretch of 2,5 m and a connection of 1,5 m.

The angle of the

connection must be 30º.

Comunication

Network

The mechanical elements of

the system will have to be activated by automatic-pneumatic mechanisms.

To do it, it must have a

parallel network signal cable and pneumatic tube that it will run in conduits

of minimum section of 60 mm. Each pair of signal cable and pneumatic tube will

run through one of these conduits. At less an empty conduit will always exist

prepared as guide for futures cables or possible extensions.

Taking care of these

criteria the characteristics of the communication installation to implant will

be:

|

Protection

Conduit |

Description |

Protection Pipe |

|

|

Material |

Polyethylene |

|

|

Diameter |

63 mm |

|

|

|

|

|

Electric

Cable |

Description |

Reinforced Cable for the

transmission of the digitalized signal. Plaited and screened cable for

special protection against external and internal interferences. |

|

|

Pairs |

2x4+2x2x0,5mm2. |

|

|

|

|

|

Pipe for the

compressed air |

Description |

Pipe for compressed air in

Polyethylene for 10 atm of pressure. |

|

|

|

Æ 16 mm / 11 mm |

|

|

|

|

|

Boxes of

conection in wells and chambers |

Weidmuller |

|

|

|

IP67 |

|

6.1.

External

inlet points

To collect 3 fractions,

there will be a total of 480 inlets outdoors, (240 inlets in each area)

We have offered in that

case the installation of those inlets in a T connection that avoid the building

of a chamber.

We have offer also of

inlet called FS. (Domestic and commercial use)

The waste is temporary stored inside the inlet, being hold through a low

discharge valve fixed to that inlet. When this valve receives the open signal

instruction from the control centre, the waste is removed and vacuum to the

collection station.

The inlet has a single disposal door where it can be deposited domestic

or commercial waste respectively. It has been defined three types of inlet

according to their use: Domestic or Commercial.

6.2.

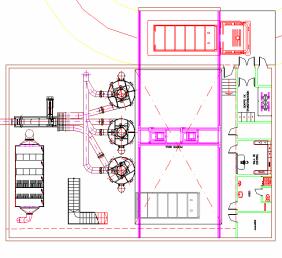

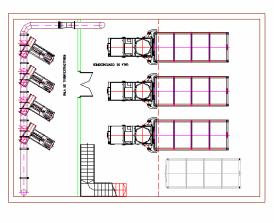

The Collection Station

The collection

station proposed is a C system designed to collect 3 fractions. As we said, to collect total area it’s need to install two

terminals.

The dimensions of the building are 21m x 28m.

The installation is developed in two plants. The height of the building will be

9.5 meters. Besides this is the height that is necessary for the accomplishment

of the maneuver of load and unloading of the truck.

The dimensions of the building are 21m x 28m.

The installation is developed in two plants. The height of the building will be

9.5 meters. Besides this is the height that is necessary for the accomplishment

of the maneuver of load and unloading of the truck.

The building counts on

the following rooms:

þ

Room of containers

Room of containers

þ

Control room

þ

Fans Room

As well the existence of

a small warehouse and a electrical cabinets rooom is recommendable that would

release of space the control room.

A transformer cabinet

room if it will be integrated in the terminal.

Control System.

Control System.

Operated by means of a

Scada system, that allows an intelligent management of the installation. The

data base of the Scada system allows as well to extract historical data of

energy consumption, running hours, alarms, etc, so that it allows a programming

of preventive maintenance oriented to objectives

Telecontrol system.

The system allows to make

a pursuit and management of the installation from Internet. This favors the

control of the installation by the customer, that could have a system of

supervision in the offices with information of the operation in real time, and

the management, update and operation of the system by means of a remote server.

Our equipment of Operation and maintenance can in this way make managements on

the installation (modifications in the programming, or management of alarms)

from any part of the world.

Smell filtration

It is fundamental to

guarantee a purification of the air of transportation, that otherwise would

cause great annoyances to the houses near the collection station.

In order to obtain the maximum effectiveness in air purification, Envac

has developed a system of filters prefabricated in factory, that they guarantee

the watertightness, as well as the maximum output of the filters. This room of

filters will be equipped with two stages with filtrate of particles and other

two stages with filters with active carbon, guaranteeing a high time of contact

of the air with the carbon, element that neutralizes the smell coming from the

waste transportation The efficiency of the purification of the air from exit to

the atmosphere has to be like minimum of 95%.

In order to obtain the maximum effectiveness in air purification, Envac

has developed a system of filters prefabricated in factory, that they guarantee

the watertightness, as well as the maximum output of the filters. This room of

filters will be equipped with two stages with filtrate of particles and other

two stages with filters with active carbon, guaranteeing a high time of contact

of the air with the carbon, element that neutralizes the smell coming from the

waste transportation The efficiency of the purification of the air from exit to

the atmosphere has to be like minimum of 95%.

Other methods of the

filtration exist but they have been demonstrated ineffective for the systems of

pneumatic collection. In the case of the biofilters, the variation of the

temperature of the air of transportation due to the heating when happening

through the fans, as well as the fact that the air flow that cross the

biofilter is discontinuous since the power station only operates during certain

hours within the day, causes that the death of the bacteria that facilitate the

air filtration.

Reserve exhauster.

Reserve exhauster.

The power necessity to

guarantee the collection of all the waste production is covered with the

installation of 2 fans of 90 Kw. However, the waste collection must be

guaranteed 24 hours to the day and 365 days to the year. For that reason, Envac

supplies the installation of one reserve fan that will guarantee the

availability of necessary power in spite of any problem with one of the others

fans. In addition the availability takes advantage of this extra fan to

alternate the running hours of the extractors and thus to guarantee a greater

life spam of the equipment, and a reduction in the maintenance cost.

6.3.

Specifications

to fulfill in the Building

Besides of geometrical

conditions, the building should be design with the observance of the next

requeritments.

Acoustic

Isolation

Acoustic isolation of the

several rooms according with the local regulations. The values of the acoustic

emissions in the several stays of the terminal, measured from a meter of the

equipment are the following ones:

þ

Fans Room 99

dB(A)

þ

Compactors 75

dB(A).

þ

Filter Room

76 dB(A).

þ

Diverter valve 79

dB(A).

Ventilation and air

conditioning

Minimun of 6 air

renovation per hour inside compactors room.

In the fans room requires

air conditioning due to the maximum temperature shouldn’t be over 35ºC.

AC in

control room

Power

Supply

Power supply from a

transformer cabinet, It could be integrated inside the building.

Collect Station of Shouthern

Hills

7.

Budget

7.1.

Estimated

budget for 2 fractions

|

PIPE NETWORK T1 |

8.970.000,00 |

|

PIPE NETWORK T2 |

7.728.000,00 |

|

OUTDOOR

INLET POINTS T1 |

5.576.002,90 |

|

OUTDOOR

INLET POINTS T2 |

5.698.292,10 |

|

TERMINAL 1 (T1) |

1.573.708,31 |

|

TERMINAL 2 (T2) |

1.573.708,31 |

|

TOTAL |

31.119.711,62 |

·

Fractions:

recyclables and rest.

·

36.300 pipe

meters.

·

230 outdoor inlet

points model FS.

·

2 C Terminal (T1

+ T2).

·

Price in €

7.2.

Estimated

budget for 3 fractions

|

PIPE NETWORK T1 |

8.970.000,00 |

|

PIPE NETWORK T2 |

7.728.000,00 |

|

OUTDOOR

INLET POINTS T1 |

5.809.787,60 |

|

OUTDOOR

INLET POINTS T2 |

5.932.076,80 |

|

TERMINAL 1 (T1) |

1.912.366,10 |

|

TERMINAL 2 (T2) |

1.912.366,10 |

|

TOTAL |

32.264.596,60 |

·

Fractions:

organic, recyclables and rest.

·

36.300 pipe

meters.

·

240 outdoor inlet

points model FS.

·

2 C Terminal (T1

+ T2).

·

Price in €

Note about the budgets:

Those prices are estimated. More detailed project should be necessary.

The scope of the price is supply, assembly, and commissioning.

Prices in EUROS

Taxes not included

Civil works are not included in this estimations.

This prices consider that our materials are excluded of custom tariff.

Changes on tariff could affect to the final prices.